-

Requirements for solids control in coalbed methane drilling

2025-12-25At present, the drilling methods for ground coalbed methane extraction mainly include conventional vertical wells, cluster wells, and multi-branch horizontal wells in terms of well types. In terms of drilling circulating media, there are mainly two methods: water-based drilling fluid and air drilling.Characteristics of coal seamsThe coal seams are usually referred to as methane gas in coal seams, which mainly exist in the coal...

-

Centrifuges in Drilling Solid Control Systems vs. Mud Conservation Systems

2025-12-25Centrifuges are commonly used in both drilling solid control systems and mud conservation systems, but what’s the difference between the centrifuges in each system?Centrifuge in Drilling Solid Control SystemsIn drilling solid control systems, the centrifuges are typically medium to low-speed ones. This is because the solid control system uses multiple stages of filtration. After the drilling fluid passes through the shale shak...

-

Comparison between skid-mounted solids control system and vehicle-mounted solids control system

2025-12-25The drilling solid control system is designed to effectively manage and separate solid particles in drilling fluids, ensuring that the drilling mud can be recycled. It's also known as the mud purification system. There are two main types of solid control systems: the skid-mounted solid control system and the truck-mounted solid control system. Both have their unique features and advantages.Skid-Mounted Solid Control System: Fe...

-

Classification and selection of solids control mud tanks

2025-12-25The mud tank in solid control systems serves as critical equipment for mud storage, blending, solid-liquid separation, and circulation. As an integral component of the mud circulation system, it facilitates mud transfer from the wellhead to mud pumps. Solid control equipment mounted on the tank separates drilling solids from the mud, which is then conditioned and blended through the weighting and mixing system to meet drilling...

-

How to deal with drilling fluid shaker screen slurry leakage

2025-12-25This phenomenon is primarily related to factors such as the high solids content in the drilling fluid, high mud viscosity, and dispersed drill cuttings. It is also related to the inherent characteristics of the shaker screen, such as low vibration force, high mesh count, and small screen area. It is also significantly affected by the direction and location of the shaker screen's inlet during on-site installation. This can be a...

-

Innovative Multi-Stage Solids Control Shale Shaker – Revolutionizing Drilling Mud Treatment

2025-12-25The innovative multi-stage solids control shale shaker is a groundbreaking advancement over traditional drilling mud shale shakers. Through technical upgrades—such as increasing the vibration motor power, replacing the single-piece screen design with modular screens, introducing a pneumatic screen tightening system instead of traditional wedge blocks, enlarging the shaker box volume and screen area—it delivers enhanced perform...

-

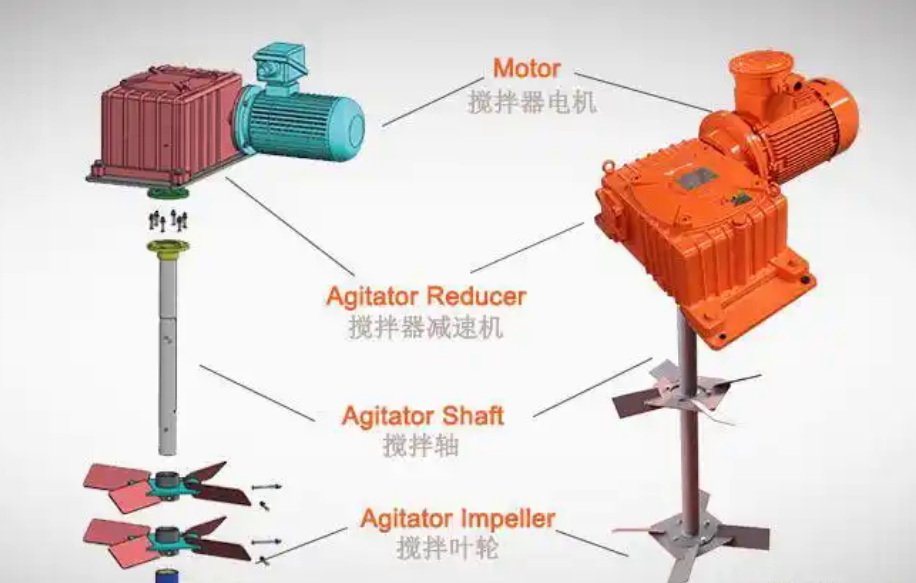

Types of Drilling Mud Agitators and Their Applications

2025-12-25Mud agitators can actually be divided into different types depending on how the gearbox and motor are connected, the shape of the impeller, the type of fluid being mixed, and their specific application. For example, by gearbox connection, they can be worm-gear type or bevel-gear type; by impeller design, they can be flat-blade, pitched-blade, or helical-blade; by flow pattern, they can be axial flow, radial flow, or mixed flow...

-

How to Select a Drilling Fluid Mud Agitator

2025-12-25A drilling fluid mud agitator is a specialized device used in petroleum drilling for solids control. It comes in various specifications and models, and agitators designed for industries like chemicals, oil refining, or food processing cannot be directly applied. Here are four key factors to consider when choosing a mud agitator, optimized for clarity and user readability based on Google search trends and user preferences.Mud A...

-

Slurry Separation System in Shield Tunneling

2025-12-25A typical slurry separation system used in shield tunneling projects consists of five main units:Slurry Separation and Treatment UnitSlurry Mixing UnitSlurry Preparation UnitSlurry Transportation UnitSlurry Monitoring and Integrated Control Unit1. Slurry Separation and Treatment UnitThe role of this unit is to separate solids and liquids from the slurry created by the cutterhead as it excavates clay and crushed rock. Multi-sta...

-

4 Common Types of Shale Shaker Screens and Their Features

2025-12-25Shale shaker screens are usually woven from metal wire or fiber wire, with an opening size between 0.15–1 mm. They are mainly used to remove and recover different types of fine suspended solids from drilling mud. Screen separation is simple, efficient, and cost-effective, which makes it a widely used method in oilfield drilling solids control systems.There are many kinds of shaker screens, but today let’s look at four of the m...

-

Differences Between Liquid-Gas Separator and Vacuum Degasser in Drilling Fluid Systems

2025-12-25Both the liquid-gas separator and the vacuum degasser are degassing devices used in drilling fluid solid control systems, but they differ significantly in their working principles and applications. The liquid-gas separator is primarily designed to remove large gas bubbles from drilling fluid, while the vacuum degasser targets smaller gas bubbles. The liquid-gas separator operates using physical principles for gas-liquid separa...

-

Understanding Drilling Fluid Centrifuges in Oilfield Mud Solid Control Systems

2025-12-25In oilfield drilling, the mud solid control system plays a critical role in maintaining the efficiency and safety of operations. One key component of this system is the drilling fluid centrifuge, which is used to separate suspensions containing solid particles with a diameter of ≥2μm. Positioned as the final stage of separation after the shale shaker and desander, the centrifuge ensures that drilling fluid (mud) is properly pr...

-

Mud Cooler: Essential Equipment for Cooling Drilling Fluid in High-Temperature Wells

2025-12-25The mud cooler is a critical piece of equipment designed to effectively reduce the temperature of drilling fluid in high-temperature, high-pressure wells, such as those used in oil, natural gas, shale gas, and shale oil exploration. Typically, a mud cooler consists of three main components: a cooling fan, a spray system, and a circulating heat dissipation system. After processing through the mud cooler, drilling mud can be coo...

-

Optimizing Oilfield Drilling with Solids Control Equipment: Installation and Maintenance Insights

2025-12-25What Does Drilling Solids Control Equipment Include?The solids control equipment in oilfield drilling operations consists of various components, including:Mud circulation systemShale shakerMud cleanerDesanderDesilterVacuum degasserDrilling fluid centrifugeShear pumpSand pumpLiquid-gas separatorElectronic ignition deviceMud agitatorJet mixing deviceMud gunMud tankSubmersible slurry pumpSolids control equipment accessoriesTypes ...

-

How Mud Guns Ensure Effective Mud Tank Cleaning: A Comprehensive Guide

2025-12-25As an auxiliary device for cleaning mud tanks, the mud gun plays an irreplaceable role in the solids control system. Also known as a drilling fluid gun or mud tank cleaning gun, the mud gun is specialized equipment designed to prevent mud sedimentation in mud tanks. It can flush and agitate dead corners that mud tank agitators cannot reach, preventing mud from settling and enabling 360-degree cleaning inside the tank. This ens...